Basic Info.

Packaging & Delivery

Product Description

Hydraulic Press Machine Structure:

Including fixed pressure process two molding methods,

The CE heat & cold process hydraulic press machine manufacturer core electrical components using Schneider brand,

And divided into general purpose, fast, additional speed, three specifications,

heat & cold machine manufacturer Body parts are always export-standard configuration.

Hydraulic cylinder with plunger pump, GB seals, the cylinder block 45 # forged steel, 45 # bar piston rod surface hardening, chrome plating.

Constant power pump hydraulic pump variable, long life and low noise.

Hydraulic pipe cold drawn seamless steel pipe, diameter flange connection to eliminate oil spills.

CE heat & cold process hydraulic press machine manufacturer Voltage using three-phase four-wire system, control panel 24V safety voltage.

Features:

This machine has independent power sector and electrical systems, and the use of relay control, can implement adjustment and semi-automatic operation. The machine working pressure, sliding fast stroke range can be adjusted according to process requirements; and to complete the process of constant pressure forming two processes given way. Constant pressure molding method after the suppression of the process, with the holding pressure and delay automatic return action.

Hydraulic Press Machine Technical Parameters:

| Items Type | Unit | Y27-60 | Y27-100 | Y27-160 | Y27-210 | Y27-250 | Y27-315 | |

| Nominal Pressure of Main Cylinder | kN | 400 | 630 | 1100 | 1500 | 1800 | 2000 | |

| Knock-Out Force of Main Cylinder | kN | 60 | 100 | 180 | 210 | 400 | 360 | |

| Main Cylinder Stroke | kN | 450 | 500 | 600 | 600 | 710 | 800 | |

| The Max.Pressure of Operating Liquid | MPa | 25 | 25 | 25 | 25 | 25 | 25 | |

| The Max.Opening from Slider to Work Table | mm | 650 | 700 | 800 | 800 | 1000 | 1100 | |

| Nominal Pressure of Hydraulic Cushion | kN | 200 | 400 | 630 | 630 | 700 | 1500 | |

| Hydraulic Cushion Stroke | mm | 200 | 200 | 250 | 250 | 300 | 300 | |

| Nominal Force of Knock-out Cylinder | kN | 15 | 15 | 20 | 20 | 30 | 40 | |

| Stroke of Knock-out Cylinder | mm | 100 | 120 | 150 | 150 | 200 | 200 | |

| Speed of Main Cylinder | Descend | mm/s | 220 | 220 | 220 | 220 | 210 | 150 |

| Working | mm/s | 20-39 | 19-30 | 15-33 | 12/25 | 10/30 | 15-30 | |

| Return | mm/s | 210 | 160 | 180 | 160 | 125 | 150 | |

| Speed of Hydraulic Cushion | Ejection | mm/s | 75 | 60 | 60 | 60 | 75 | 50 |

| Active Area of Working Table(E×D) | Left-Right | mm | 550 | 610 | 710 | 710 | 790 | 1200 |

| Front-Back | mm | 600 | 750 | 850 | 850 | 900 | 1260 | |

| Table Height(I) | mm | 900 | 920 | 950 | 970 | 750 | 600 | |

| Electric Motor Power | kW | 7.5 | 11 | 15 | 15 | 22 | 30 | |

Hydraulic Press Machine Workshop Processing:

Y32.three beam four column hydraulic press Usage:

1.Auto parts:

automobile body covering parts, braking, fuel tanks, chassis, axle case , bumper.

2. Household appliances:

washing machine , TV, refrigerator ,air conditioning, rice cooker and other parts .

3.Kitchenware:

sink ,tea set and Other kinds of containers .

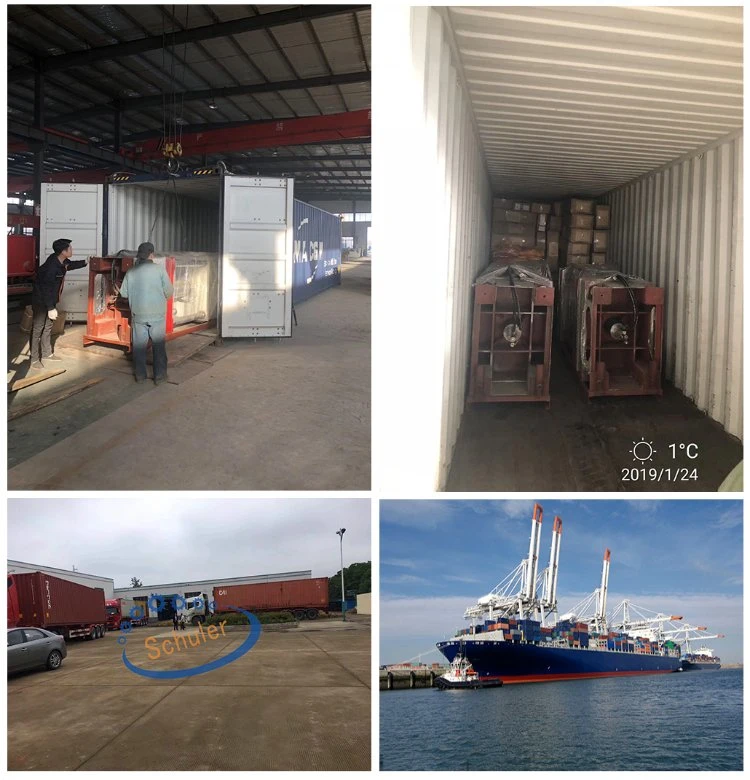

Hydraulic Press Machine Package Delivery:

---->We can guarantee on-time delivery

---->Packing: The machine and accessories are fixed in the wooden box, then spray anti-corrosion oil, hang up the desiccant to ensure the safety of the machine during long-term transportation.

---->Export case: wooden box with Tito, two, fumigation wooden box,

---->Mode of transport: transported by sea or rail to the customer's location.

FAQ

1. What level of service do you provide ?

--->Your inquiry will be replied within 24 hours.

2. Technology support by providing operation?training videos?

---->Professional after-sales service team.

We can Provide Technical support online service and Machine operation Vedio

We can provide on-site training and commissioning Vedio

We can Provide Spare parts replacement and repair service

Give reasonable offers with the best quality.

3. What is our advantages?

----> Competitive price: We can meet your budget and best-selling business very well.

OEM Accepted: We can produce customized design.

Good Service: We treat clients as friends and provide problem solving anytime you need.

Good Quality: We have strict quality control system. Good reputation in the market.

Fast & Delivery: We have big discount from forwarder (Long-term Contract).

4. Can you customize the machine for the customer?

---->Yes. We can, if you need customized services, please contact us

5. What is the MOQ?

---->We usually provide 1 set for customers to test.

6.What is your delivery time?

---->The delivery depends on different machines with different configurations. Please contact us to confirm it is in stock or not.

7.What is your payment method?

---->We prefer to do 100% T/T (30% T/T in advance, 70% T/T before shipment)

8.Agents Wanted:

---->We have strong partnerships in Europe, America, South America, India, Southeast Asia and South Africa. We also supply OEM service, and we are looking for agents in these areas. In the further, we want to develop SCHULER to a global brand. Wherever you are from, we are looking forward to explore new market with you.

Contact information :

Shandong Schuler CNC Machinery Co.,Ltd.

Add: Tengzhou City ,Shandong Province ,China

Edwin

Mob: +86-18663288651