- Overview

- Product Description

- Product Parameters

- Detailed Photos

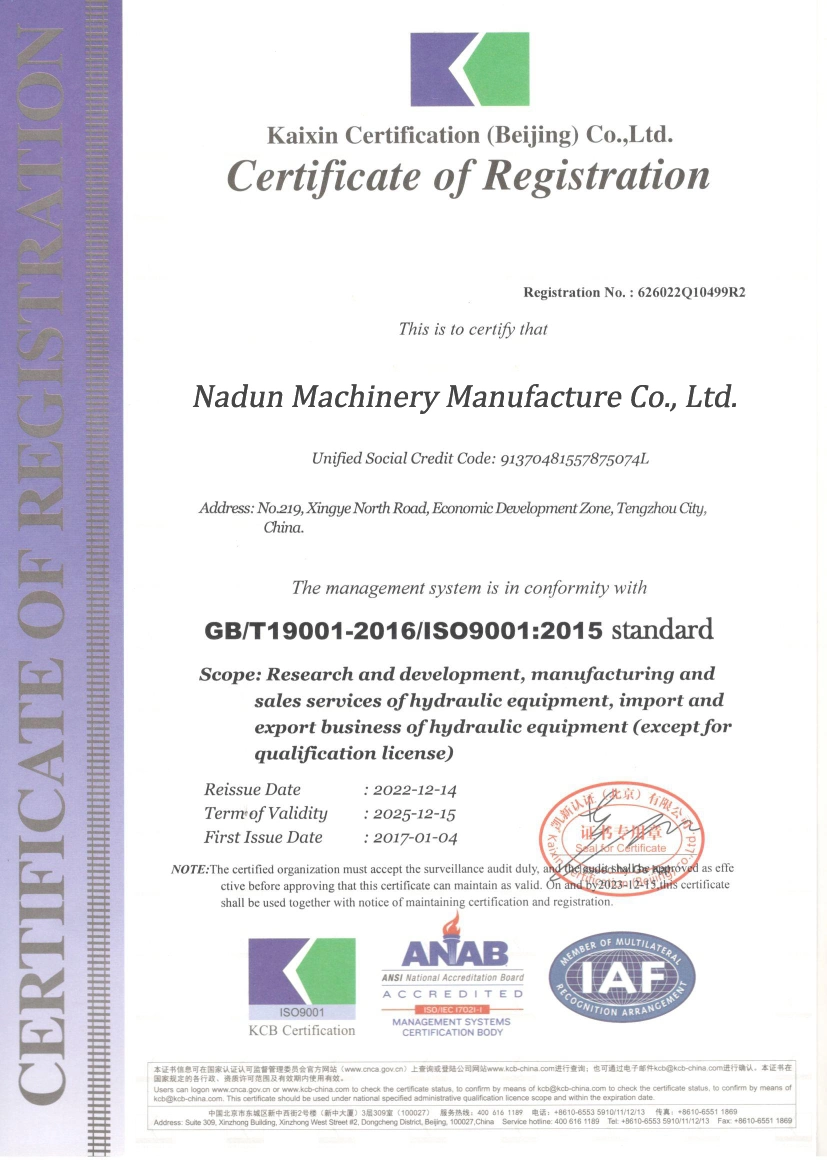

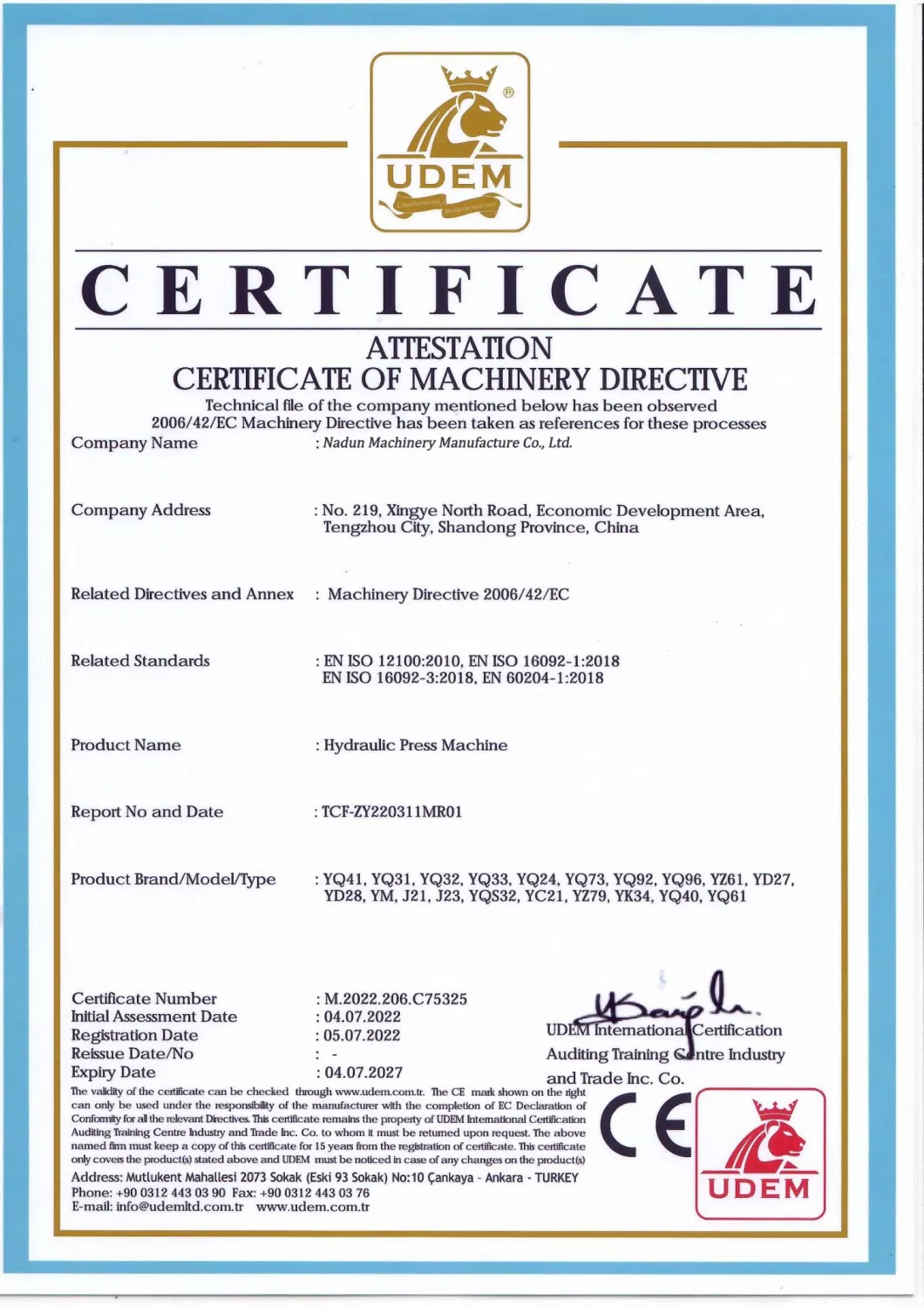

- Certifications

- Company Profile

- Packaging & Shipping

- FAQ

Basic Info.

Packaging & Delivery

Product Description

1.Characterized by good structural rigidity, excellent guiding performance, and fast speed.

2.The convenient manually adjustable mechanism allows for adjusting the ram or upper worktable to any position during the stroke for pressing. It can also adjust the length of rapid approach and working stroke within the designed stroke.

3.The overall welded robust open structure keeps the machine body rigid while providing the most convenient operating space.

Performance Features:

1.Utilizes computer-optimized structural design, single-arm machine body structure, good rigidity, simple structure, and user-friendly operation.

2.The entire machine is welded with steel plates and undergoes furnace annealing treatment.

3.Hydraulic control adopts a two-way cartridge valve integrated system, ensuring reliable operation, intuitive movements, and easy maintenance. It uses a centralized control panel with buttons, offering three operation modes: adjustment, manual, and semi-automatic (which can be further divided into fixed-stroke single cycle and fixed-pressure single cycle).

4.The working pressure of the slide, the stroke range of rapid descent under no load, and the slow-speed working approach can all be adjusted according to process requirements. The models in the table below are our standard models for the C-Type Hydraulic Press. We can also customize according to your specific requirements.The parameters highlighted in brown below are specific to the YQ41-10T model.

| Parameter Names | UNIT | YQ41-10 | YQ41-40 | YQ41-63 | YQ41-100 | YQ41-160 | YQ41-200 | YQ41-250 | YQ41-315 | YQ41-500 |

| Nominal Force | KN | 200 | 400 | 630 | 1000 | 1600 | 2000 | 2500 | 3150 | 5000 |

| Effective Stroke | mm | 260 | 260 | 280 | 320 | 360 | 400 | 400 | 500 | 500 |

| Open Height | mm | 600 | 600 | 700 | 700 | 800 | 1000 | 1000 | 1200 | 1200 |

| Throat Depth | mm | 200 | 220 | 240 | 280 | 320 | 360 | 420 | 500 | 600 |

| Down Speed | mm/s | 16 | 19 | 13 | 10 | 13 | 15 | 15 | 50 | 50 |

| Return Speed | mm/s | 19 | 25 | 17 | 13 | 20 | 20 | 20 | 60 | 55 |

| Worktable Left-Right | mm | 500 | 500 | 600 | 700 | 700 | 800 | 900 | 1050 | 1200 |

| Worktable Front-Back | mm | 400 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | 1050 |

| Material Hole Diameter | mm | 80 | 100 | 120 | 200 | 200 | 220 | 220 | 240 | 240 |

Our company has a team of experienced professionals who consistently strive for excellence in their work. We have a strong research and development team that constantly innovates and improves our products to meet the ever-changing market demands. Our products are known for their high quality, excellent performance, and long service life.

At Nadun Machinery Manufacture Co., Ltd., we take pride in our commitment to providing customers with exceptional products and services. We have strict quality control procedures in place to ensure that each product meets or exceeds our customers' expectations. Furthermore, we offer customized solutions to meet specific customer requirements.

We believe that our success is closely tied to the success of our customers. For this reason, we work hard to build strong relationships with our customers and offer them the support and guidance they need to achieve their goals.

If you are interested in learning more about our products or services, please do not hesitate to contact us. We look forward to the opportunity to work with you and provide you with the best solutions for your needs.

2. Package equipment in wooden crates with a stable structure capable of withstanding pressure. Customization based on equipment dimensions helps avoid compression.

3. Load packaged equipment into containers. Containers can carry a large quantity of goods, optimize internal space, enhance transportation efficiency, and are universally accepted globally.

4. Transport containers to ports using trucks, choose routes with good road conditions, control driving speed to minimize impact.

5. Load containers onto ships at the port, using ships for worldwide transportation, suitable for long-distance international shipments.

6. For inland countries, opt for transportation by train. Trains offer high speed, pass through major cities, facilitate goods transfer, and have a large carrying capacity.

1. What types of machinery does Nadun Machinery Manufacture Co., Ltd. specialize in producing?

- Nadun Machinery Manufacture Co., Ltd. specializes in the production of hydraulic presses, punch presses, shearing machines, bending machines, and other machinery.

2. Which industries are the products of Nadun Machinery widely used in?

- Nadun Machinery's products find applications in various industries such as automobile manufacturing, home appliances, and hardware processing.

3. What are the key features of the C-Type Hydraulic Press offered by Nadun Machinery?

- The C-Type Hydraulic Press is characterized by good structural rigidity, excellent guiding performance, and fast speed. It also has a convenient manually adjustable mechanism for adjusting the ram or upper worktable during the stroke.

4. How does Nadun Machinery ensure the quality of its products?

- Nadun Machinery has strict quality control procedures in place to ensure that each product meets or exceeds customer expectations. The company utilizes a computer-optimized structural design and undergoes furnace annealing treatment for its products.

5. What customization options does Nadun Machinery offer to its customers?

- Nadun Machinery provides customized solutions to meet specific customer requirements, ensuring that their products align with the unique needs of each customer.

6. What are the performance features of Nadun Machinery's hydraulic presses, particularly in terms of structural design and control systems?

- Nadun Machinery's hydraulic presses utilize a single-arm machine body structure, computer-optimized structural design, and a two-way cartridge valve integrated system for hydraulic control. The control panel offers three operation modes: adjustment, manual, and semi-automatic. Adjustments can be made for working pressure, stroke range, and slow-speed working approach according to process requirements.