Basic Info.

Model NO.

standard and customized

HRC

50-62

Size

up to 6000mm

Transport Package

Wooden Case

Specification

customized

Trademark

ZUQIU

Origin

Anhui, China

HS Code

8480490000

Production Capacity

50000pieces/Year

Product Description

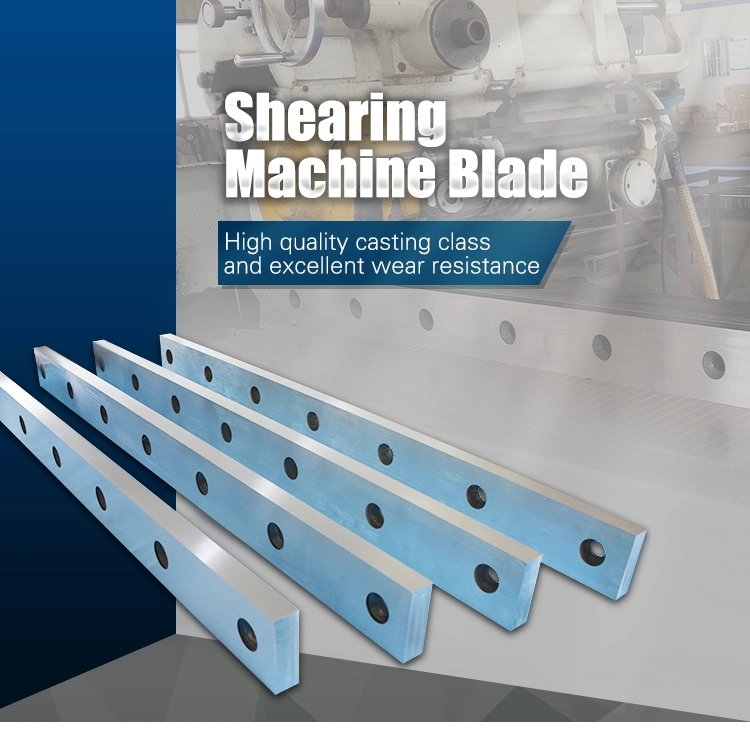

Shear blades with direct factory Price for you.

Do you have any trouble with your current straight cutting blade?

Are your straight cutting blades not a good suite to your process?

Does it get broken or need re-sharpening all the time?

Let us help you get the most performance straight cutting blade for you.

As a professional manufacturer of high quality mechanical and industrial blades, Jiangnan produces various straight cutting blades. Our range of products: cutting blades for wood industries, plastic industries, metal industries

All our straight cutting blades are manufactured to exceed our customers' requirements at a competitive price and timely shipment, and meet all OEM specifications by manufactured from a wide range of materials including Tungsten Carbide, Tooling steels, such as D2, SKD11, SKH51, M2 etc.

With our optimized solutions specifically designed for each customer's needs, Jiangnan has helped many clients resolve their blades performance issues and optimize their cutting processes for the last 25 years. Fully take advantage of our expertise and technology today and please contact us now!

Operation Progress:

Material and hardness are much important to the work life for blades, according to over 25 years' experience, Jiangnan can provide you professional advice and recommend you most suitable material and hardness according to the applications of blades with competitive price.

Material and hardness are much important to the work life for blades, according to over 25 years' experience, Jiangnan can provide you professional advice and recommend you most suitable material and hardness according to the applications of blades with competitive price.

In order to provide prompt and accurate quotation, it's better that you can provide us the quantity, drawings, cutting application and etc.

Packaging Details,

1, PE film or Kraft paper in anti-rust oil - keep air/water/humid away, thus rust-proofing.

2, Bubble Wrap - increases the impact resistance ability.

3, Rubber Slip or Corrugated Angle - gives special care to knife edges.

4, Wood Screws crates - makes opening easier without damaging the crates

5, Corrugated boxes or plywood case - provide superior protection and stack-ability

All of your inquiry and emails will be replied within 24 hours.We look forward to work with you in the near future. And you are highly welcome to visit our factory.

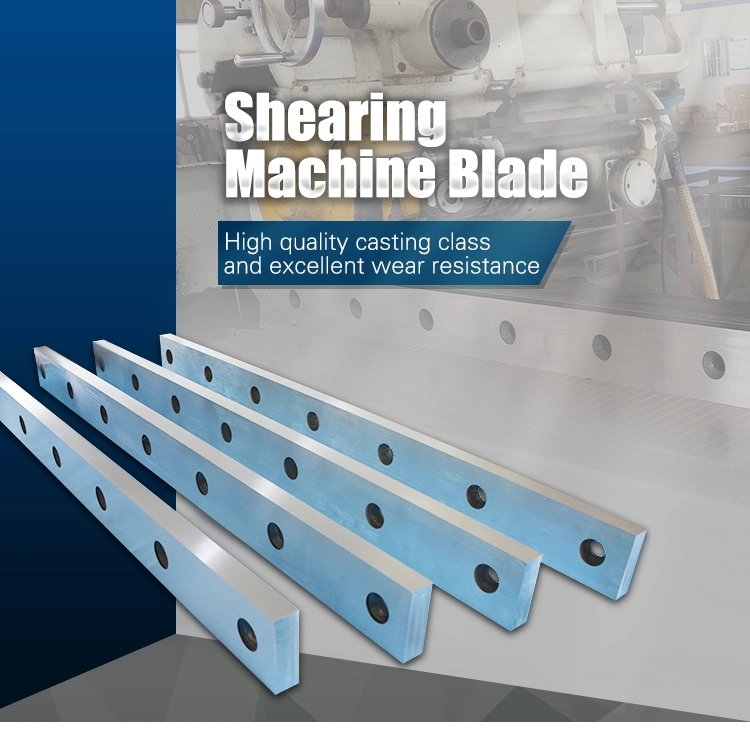

Do you have any trouble with your current straight cutting blade?

Are your straight cutting blades not a good suite to your process?

Does it get broken or need re-sharpening all the time?

Let us help you get the most performance straight cutting blade for you.

As a professional manufacturer of high quality mechanical and industrial blades, Jiangnan produces various straight cutting blades. Our range of products: cutting blades for wood industries, plastic industries, metal industries

All our straight cutting blades are manufactured to exceed our customers' requirements at a competitive price and timely shipment, and meet all OEM specifications by manufactured from a wide range of materials including Tungsten Carbide, Tooling steels, such as D2, SKD11, SKH51, M2 etc.

With our optimized solutions specifically designed for each customer's needs, Jiangnan has helped many clients resolve their blades performance issues and optimize their cutting processes for the last 25 years. Fully take advantage of our expertise and technology today and please contact us now!

Operation Progress:

Material and hardness are much important to the work life for blades, according to over 25 years' experience, Jiangnan can provide you professional advice and recommend you most suitable material and hardness according to the applications of blades with competitive price.

Material and hardness are much important to the work life for blades, according to over 25 years' experience, Jiangnan can provide you professional advice and recommend you most suitable material and hardness according to the applications of blades with competitive price. In order to provide prompt and accurate quotation, it's better that you can provide us the quantity, drawings, cutting application and etc.

| MATERIAL TO CHOOSE | |||||||||

| GB | ASTM | JIS | DIN | W-Nr | NF | ROCT | SS14 | BS | ISO |

| 9CrSi | - | - | 90CrSi5 | 1.2108 | - | 9XC | 2090 | - | - |

| 6CrW2Si | - | - | 60WCrV7 | 1.255 | 55WC20 | 6XB2C | - | - | 60WCrV7 |

| Cr12MoV | - | SKD11 | X165CrMoV12 | 1.2601 | - | X12M | 2310 | - | - |

| Cr12Mo1V1 | D2 | - | X155Cr12Mo12-1 | 1.2379 | X160CrMoV12 | - | - | BD2 | 160CrMoV12 |

| 4Cr5MoSiV1 | H13 | SKD61 | X40CrMoV5-1 | 1.2344 | X40CrMoV5 | 4X5MO1C | - | BH13 | 40CrMoV5 |

| LD | - | - | - | - | - | - | - | - | - |

| W18Cr4V | T1 | SKH2 | S18-0-1 | 1.3355 | HS18-0-1 | P18 | 2750 | BT1 | HS18-0-1 |

| W6Mo5Cr4V2 | M2 | SKH9 | S6-5-2 | 1.3343 | - | P6M5 | 2722 | BM2 | HS6-5-2 |

| 45 | 1450 | S45C | C45E | 1.1191 | C45E | 45 | 1660 | C40E | C45EC |

| 42CrMo | 4140 | SCM44O | 42CrMo4 | 1.7225 | 42CD4 | - | 2244 | 708M40 | 42CrMo4 |

| T8 | w1a-8 | SK5 | C80W2 | 1.1625 | C80E2U | Y6 | 1778 | - | TC80 |

Packaging Details,

1, PE film or Kraft paper in anti-rust oil - keep air/water/humid away, thus rust-proofing.

2, Bubble Wrap - increases the impact resistance ability.

3, Rubber Slip or Corrugated Angle - gives special care to knife edges.

4, Wood Screws crates - makes opening easier without damaging the crates

5, Corrugated boxes or plywood case - provide superior protection and stack-ability

All of your inquiry and emails will be replied within 24 hours.We look forward to work with you in the near future. And you are highly welcome to visit our factory.