- Overview

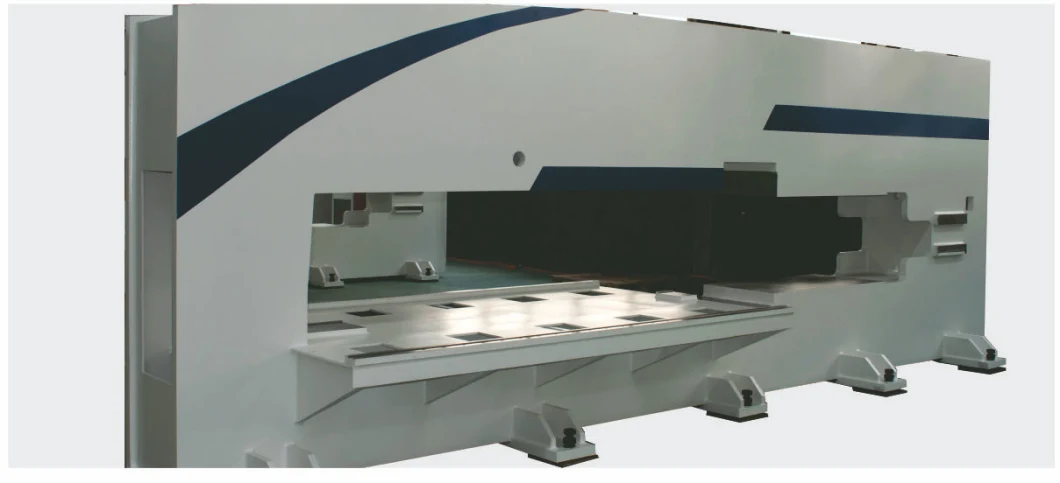

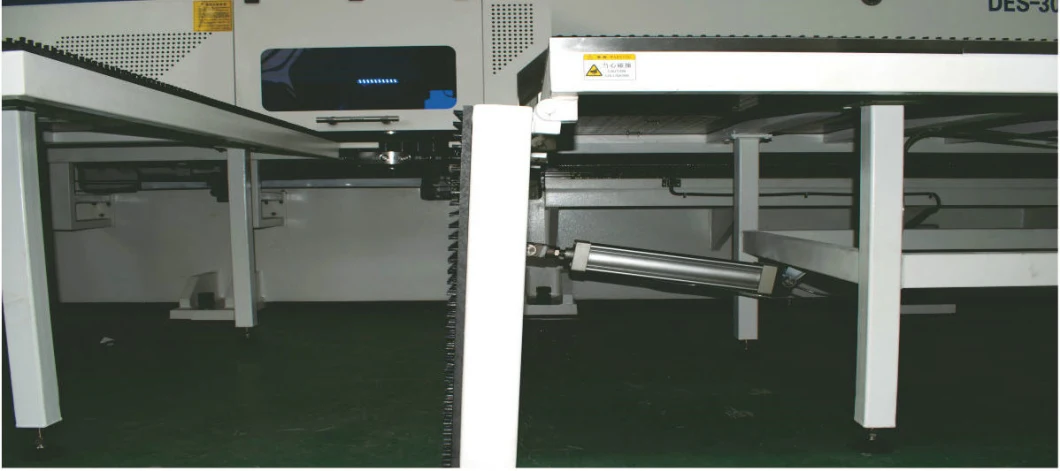

- Detailed Photos

- Punching Model

- Product Parameters

- product category

- Certifications

- Company Profile

- FAQ

Basic Info.

Model NO.

DES-300

Punch Shape

Closed Punch

Slider Movement

Double Action

Slider Drive Mechanism

Cam Press

Controlling Mode

CNC

Automatic Grade

Automatic

Power Source

Electric

Precision

High Precision

Certification

GS, CE, RoHS, ISO 9001

Condition

New

Punch Force

30 Kn

Max. Processing Sheet

2500* 1250 mm

Max. Processing Sheet Thickness

6.35 mm

Max. Punch Diameter

88.9 mm

Accuracy

±0.1 mm

Servo Unit

Panasonic, Synmot, Sano

Loading

20ot, 40gp Container

Package

Foam and Plastic Film, Customized

Color

Blue, Red, Customized

Linear Guide and Ball Screw System

Japan NSK/ Tsubaki, Taiwan Hiwin/Tbi

Transport Package

Pallet, Foam and Plastic Film

Specification

5200*5200*2280 MM

Trademark

Dontzer

Origin

China

HS Code

8462421200

Production Capacity

200 Sets/Year

Packaging & Delivery

Package Size

12.03cm * 2.35cm * 2.39cm

Package Gross Weight

16000.000kg

Product Description

Portable Turret Cutting Forming Shearing Punching machine Metal Sheet Tube and Plate with Japan Electrical Components

* Thick rotating tower

* Extending mold life

* High accuracy

* Extending mold life

* High accuracy

* Steel plate frame

* Tempering fireplace

* One-step clamping

* Tempering fireplace

* One-step clamping

* Automatic electric lifting table

* Fully automatic floating clamo

* Connecting slide and clamp by dovetailing

* Connecting slide and clamp by dovetailing

| ITEMS | UNIT | SPECIFICATIONS |

| Punch Force | KN | 30 |

| Frame Structure | / | O type |

| Max. Processing Sheet (Reposition) | MM | X-axis 5000 |

| Y-axis 2000 | ||

| Max. Processing Sheet Thickness | MM | 6.35 |

| Max. Punch Diameter | MM | Φ88.9 |

| Punch Pace | HPM | 1800 |

| Max. Punch Hit at 1mm Pace | HPM | 800 |

| Max. Punch Hot at 25.4mm Pace | HPM | 400 |

| No. Of Tool Station | No. | 16/24/32 |

| Controlling Axis | N0. | 5 (X/Y/R/T/C) |

| Mould Structure | / | International Standard Mould |

| Reposition Cylinder | Set | 2 |

| Max. Steel Moving Speed | M/min | 106 |

| Tooling Rotation Speed | Rpm | 30 |

| Accuracy | mm | ±0.1 |

| Max. Load Weight | Kg | 156 |

| Air Pressure | MPa | 0.6 |

| Power | V | 380± 5% |

| Total Weight | T | 20 |

| Outline Dimension | mm | 6400*5200*2280 |

1. How about the delivery time?

Generally it's 15-30 days based on the model.

2. How is the warranty time?

1 year after installation.

Lifetime free technical support.

3. How to choose the suitable machine?

Please advise us the material/ thickness/ dimension of metal sheet, and the punched drawing.