Basic Info.

Model NO.

JH21

Controlling Mode

Artificial

Automatic Grade

Automatic

Power Source

Mechanical Drive

Precision

High Precision

Certification

GS, CE, RoHS, ISO 9001

Condition

New

Power Press

C Frame Mechanical Power Press

Control System

PLC with Interface

Clutch Type

Wet Type Pneumatic Clutch

Lubrication System

Automatic Grease Pump

Overload System

Hydraulic Overload Protection

Press Color

Grey or Customized

Transport Package

Steel Pallet

Specification

press capacity from 25 tons to 400 tons

Trademark

WORLD

Origin

China

HS Code

84629910

Production Capacity

2000PCS

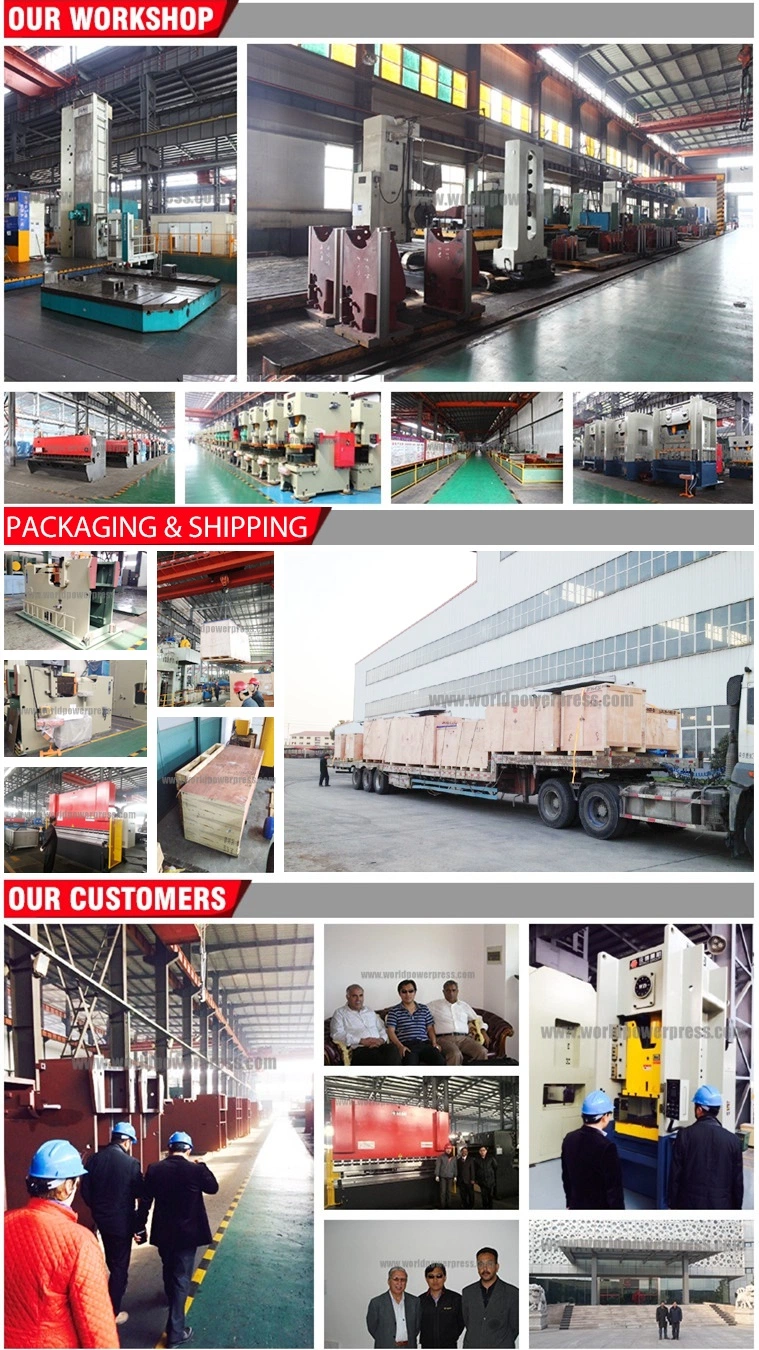

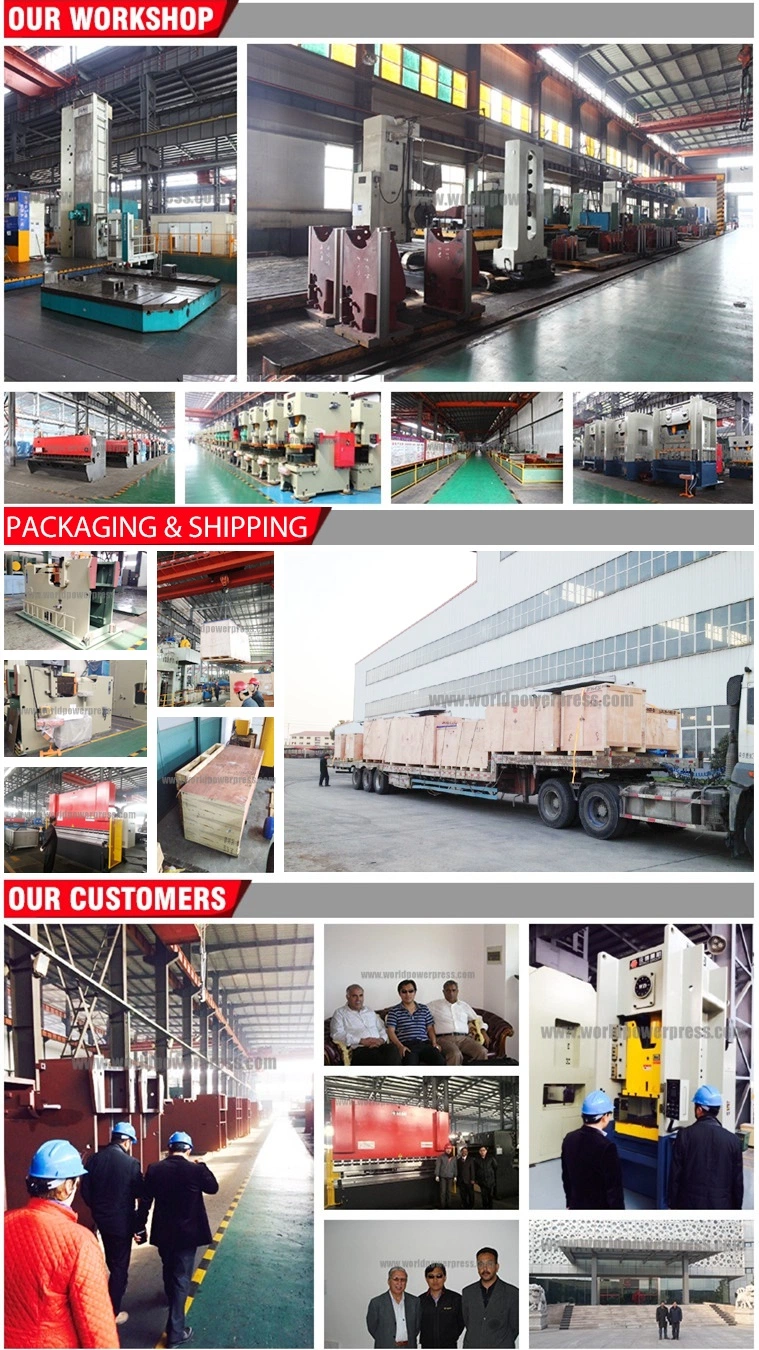

Product Description

World precise machinery C frame pneumaitc power press, tonnage range from 25ton to 400ton. This c frame press adopts steel plate welded body. Welding parts are all anealing treatment. JH21 pneumatic press has hydraulic overload protection system. The wet type pneumaitc clutch is easier for maintenance. And the noise is smaller.

C frame mechanical power press is widely used for sheet metal stamping, piercing, trimming and bending process. The power press could work with single punch die and progressive die to produce home appliance parts, tv brackets, auto parts, utensils and similar stamping parts. The press could work with NC feeder decoiler system to act as an automatic press line.

Features:

1. Steel welded body, tempering treatment, high rigidity, accuracy and stability;

2. Vertical located crankshaft, compact structure;

3. The crankshaft undergoes grinding treatment after high frequency quenching;

4. Lengthened rectangular guideway with a surface of bronze plate;

5. Pneumatic dual balance cylinder, which balances the slide block and punch weight to reduce noise and impact;

6. PLC control and imported safety dual valve;

7. Wet clutch and hydraulic overload protector.

8. CE certificate

Details:

1. Steel plate welded c frame body, heat treatment, produced by cnc boring and milling center, high rigidity and precission

2. Wet type pneumatic clutch with safety solenoid valve, lower noise and longer service life.

3. Best quality gears, bushes, cylinders, link rods and ball screw ensure the high performance, high reliability and longer service life.

4. Hydraulic overload protected system is standard equipped. The press will stop with oil pressure release if overload to protect the press and the die. It is easy to reset to normal status.

5. PLC control, Omron or Panasonic brand, high quality with global warranty.

6. Double hands control buttons, touch screen control panel, cam controller with encoder.

7. Slide adjust motor is equipped on the back of the slide. This position is better to protect the motor and the press is more compact in this way. The slide is motorized adjusted with digital displayer.

8. Center auto grease lubrication system is standard equipped and the lubrication frequency can be setted with the touchscreen. In the meanwhile, manual thin oil lubrication system is equipped too.

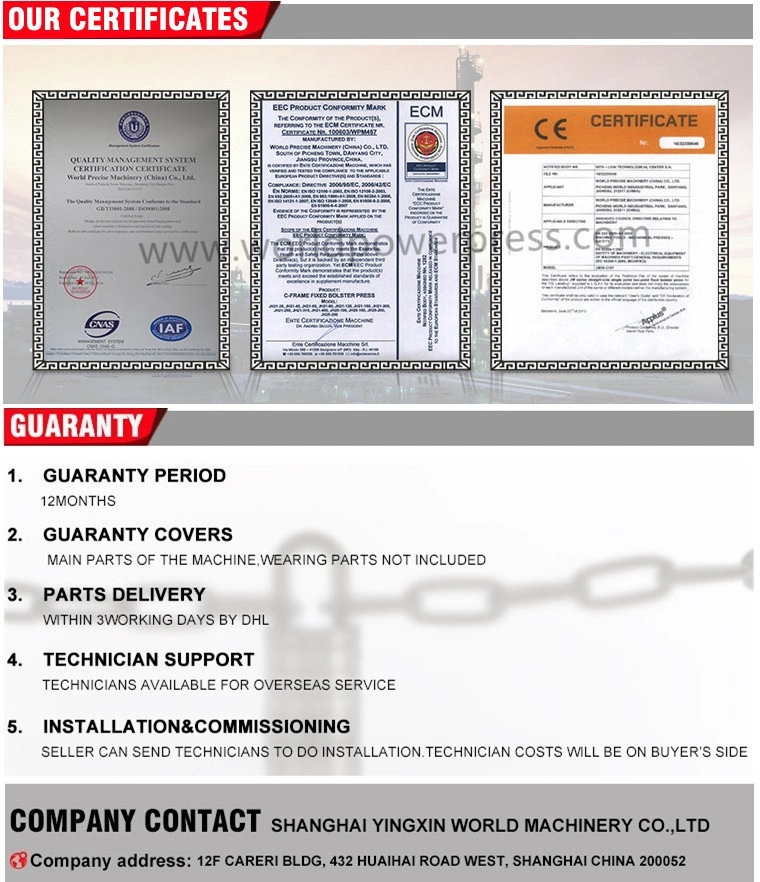

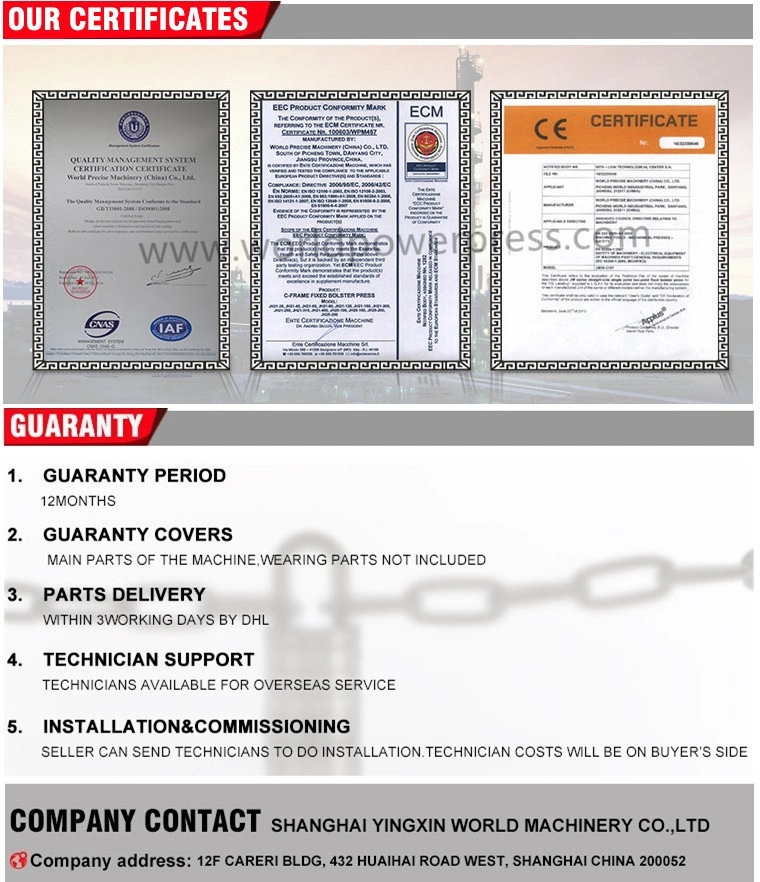

Options: Quality certificate:

- light curtain for safety - ISO 9001

- inverter for adjustable stroke speed - CE

- variable speed motor for adjustable stroke speed - SGS inspection if needed

- cushion

- hydraulic die quick change device

Warranty and service:

- one year warranty for whole press.

- all spare parts are available as we produce most of the parts in our factory.

- it is easy to get the electric parts as all are international famous brands.

- we can provide technical support via email, phone or video.

- we can send out engineers for service, installation or training with reasonable additional cost.

- English operation and maintenance manual is provided with the press.

- All safety warning tags and control panels are in English.

Our products range:

- J23 and JH23 inclinable eccentric press, capacity from 6.3ton to 125ton.

- JH21 c frame single crank press, capacity from 25ton to 400ton.

- JH31 semi-straight side single crank press, capacity from 110ton to 400ton.

- JW31 H frame single crank press, capacity from 110ton to 400ton.

- JH25 c frame double crank press, capacity from 110ton to 315ton.

- JW36 H frame double crank press, capacity from 110ton to 500ton.

- JX36 close type big table press with double crank, capacity from 400ton to 1000ton.

- JS36 close type gear press, capacity from 300ton to 1250ton.

- JS31 close type gear press, capacity from 160ton to 1000ton.

- NCF roller feeder

- 3 in 1 straightener feeder with decoiler

- hydraulic shearing machine

- hydraulic press brake and cnc press brake

- hydraulic press machine

Specifications: Eccentric metal stamping Punching Power Press Machine

C frame mechanical power press is widely used for sheet metal stamping, piercing, trimming and bending process. The power press could work with single punch die and progressive die to produce home appliance parts, tv brackets, auto parts, utensils and similar stamping parts. The press could work with NC feeder decoiler system to act as an automatic press line.

Features:

1. Steel welded body, tempering treatment, high rigidity, accuracy and stability;

2. Vertical located crankshaft, compact structure;

3. The crankshaft undergoes grinding treatment after high frequency quenching;

4. Lengthened rectangular guideway with a surface of bronze plate;

5. Pneumatic dual balance cylinder, which balances the slide block and punch weight to reduce noise and impact;

6. PLC control and imported safety dual valve;

7. Wet clutch and hydraulic overload protector.

8. CE certificate

Details:

1. Steel plate welded c frame body, heat treatment, produced by cnc boring and milling center, high rigidity and precission

2. Wet type pneumatic clutch with safety solenoid valve, lower noise and longer service life.

3. Best quality gears, bushes, cylinders, link rods and ball screw ensure the high performance, high reliability and longer service life.

4. Hydraulic overload protected system is standard equipped. The press will stop with oil pressure release if overload to protect the press and the die. It is easy to reset to normal status.

5. PLC control, Omron or Panasonic brand, high quality with global warranty.

6. Double hands control buttons, touch screen control panel, cam controller with encoder.

7. Slide adjust motor is equipped on the back of the slide. This position is better to protect the motor and the press is more compact in this way. The slide is motorized adjusted with digital displayer.

8. Center auto grease lubrication system is standard equipped and the lubrication frequency can be setted with the touchscreen. In the meanwhile, manual thin oil lubrication system is equipped too.

Options: Quality certificate:

- light curtain for safety - ISO 9001

- inverter for adjustable stroke speed - CE

- variable speed motor for adjustable stroke speed - SGS inspection if needed

- cushion

- hydraulic die quick change device

Warranty and service:

- one year warranty for whole press.

- all spare parts are available as we produce most of the parts in our factory.

- it is easy to get the electric parts as all are international famous brands.

- we can provide technical support via email, phone or video.

- we can send out engineers for service, installation or training with reasonable additional cost.

- English operation and maintenance manual is provided with the press.

- All safety warning tags and control panels are in English.

Our products range:

- J23 and JH23 inclinable eccentric press, capacity from 6.3ton to 125ton.

- JH21 c frame single crank press, capacity from 25ton to 400ton.

- JH31 semi-straight side single crank press, capacity from 110ton to 400ton.

- JW31 H frame single crank press, capacity from 110ton to 400ton.

- JH25 c frame double crank press, capacity from 110ton to 315ton.

- JW36 H frame double crank press, capacity from 110ton to 500ton.

- JX36 close type big table press with double crank, capacity from 400ton to 1000ton.

- JS36 close type gear press, capacity from 300ton to 1250ton.

- JS31 close type gear press, capacity from 160ton to 1000ton.

- NCF roller feeder

- 3 in 1 straightener feeder with decoiler

- hydraulic shearing machine

- hydraulic press brake and cnc press brake

- hydraulic press machine

Specifications: Eccentric metal stamping Punching Power Press Machine

| ITEM | CODE | UNIT | JH21-25 | JH21-45 | JH21-60 | JH21-80 | JH21-100 | JH21-125 | |

| Nominal Capacity | Pe | KN | 250 | 450 | 600 | 800 | 1000 | 1250 | |

| Slide Stroke Length | S | mm | 80 | 120 | 140 | 160 | 160 | 180 | |

| Rated Tonnage Point | mm | 3 | 4 | 4 | 5 | 5 | 6 | ||

| Slide Strokes | Fixed | spm | 100 | 80 | 70 | 60 | 55 | 50 | |

| Variable (optional) | spm | 60-120 | 50-95 | 45-85 | 40-75 | 35-65 | 35-60 | ||

| Max. Die Shut Height | H2 | mm | 250 | 270 | 300 | 320 | 335 | 350 | |

| Die Shut Height Adjustment | t | mm | 50 | 60 | 70 | 80 | 90 | 90 | |

| Throat Depth | C1 | mm | 210 | 225 | 270 | 310 | 330 | 350 | |

| Distance Between Uprights | d1 | mm | 470 | 525 | 560 | 580 | 670 | 630 | |

| Slide Bottom Size | LR | b | mm | 360 | 400 | 480 | 540 | 620 | 620 |

| FB | a | mm | 250 | 340 | 400 | 460 | 520 | 520 | |

| Shank Hole Size | Diameter | d | mm | 40 | 50 | 50 | 50 | 70 | 70 |

| Depth | I | mm | 50 | 60 | 70 | 70 | 80 | 80 | |

| Table Size | LR | D | mm | 720 | 825 | 930 | 950 | 1060 | 1100 |

| FB | C | mm | 400 | 440 | 520 | 600 | 640 | 680 | |

| Thickness | H3 | mm | 80 | 110 | 130 | 140 | 145 | 155 | |

| Table Hole Diameter | ¢ | mm | 150 | 150 | 150 | 180 | 180 | 200 | |

| Bolster Surface Height | H1 | mm | 750 | 775 | 800 | 845 | 850 | 850 | |

| Overall Dimensions | FB | A | mm | 1500 | 1585 | 1540 | 1765 | 2000 | 2040 |

| LR | B | mm | 945 | 1075 | 1200 | 1200 | 1300 | 1320 | |

| Height | H | mm | 2090 | 2365 | 2470 | 2675 | 2960 | 2980 | |

| Motor Power | KW | 3 | 5.5 | 5.5 | 7.5 | 7.5 | 11 | ||

| Air Pressure | Mpa | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | ||

| ITEM | CODE | UNIT | JH21-160 | JH21-200 | JH21-250 | JH21-315 | JH21-400 | |

| Nominal Capacity | Pe | KN | 1600 | 2000 | 2500 | 3150 | 4000 | |

| Slide Stroke Length | S | mm | 200 | 200 | 220 | 220 | 250 | |

| Rated Tonnage Point | mm | 6 | 6 | 6.5 | 7 | 8 | ||

| Slide Strokes | Fixed | spm | 45 | 45 | 30 | 30 | 30 | |

| Variable (optional) | spm | 30-55 | 30-55 | 20-35 | 20-35 | 20-35 | ||

| Max. Die Shut Height | H2 | mm | 400 | 450 | 500 | 500 | 550 | |

| Die Shut Height Adjustment | t | mm | 100 | 110 | 120 | 120 | 120 | |

| Throat Depth | C1 | mm | 400 | 430 | 450 | 450 | 450 | |

| Distance Between Uprights | d1 | mm | 676 | 910 | 980 | 980 | 1050 | |

| Slide Bottom Size | LR | b | mm | 700 | 880 | 950 | 950 | 1020 |

| FB | a | mm | 580 | 650 | 700 | 700 | 750 | |

| Shank Hole Size | Diameter | d | mm | 70 | 70 | 70 | 70 | 70 |

| Depth | I | mm | 100 | 100 | 100 | 100 | 100 | |

| Table Size | LR | D | mm | 1175 | 1390 | 1500 | 1540 | 1700 |

| FB | C | mm | 760 | 840 | 880 | 880 | 880 | |

| Thickness | H3 | mm | 165 | 180 | 190 | 190 | 210 | |

| Table Hole Diameter | ¢ | mm | 220 | 240 | 240 | 240 | 240 | |

| Bolster Surface Height | H1 | mm | 900 | 1000 | 1000 | 1000 | 1100 | |

| Overall Dimensions | FB | A | mm | 2305 | 2600 | 2660 | 2720 | 2850 |

| LR | B | mm | 1420 | 1540 | 1640 | 1680 | 1750 | |

| Height | H | mm | 3210 | 3800 | 3850 | 3850 | 4140 | |

| Motor Power | KW | 15 | 18.5 | 22 | 30 | 37 | ||

| Air Pressure | Mpa | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | ||