Basic Info.

Model NO.

TC-1270

Performance Classification

High-End CNC Machine Tools

Certification

CE

Condition

New

Table Size

1360*700mm

Table Max Load

1300kg

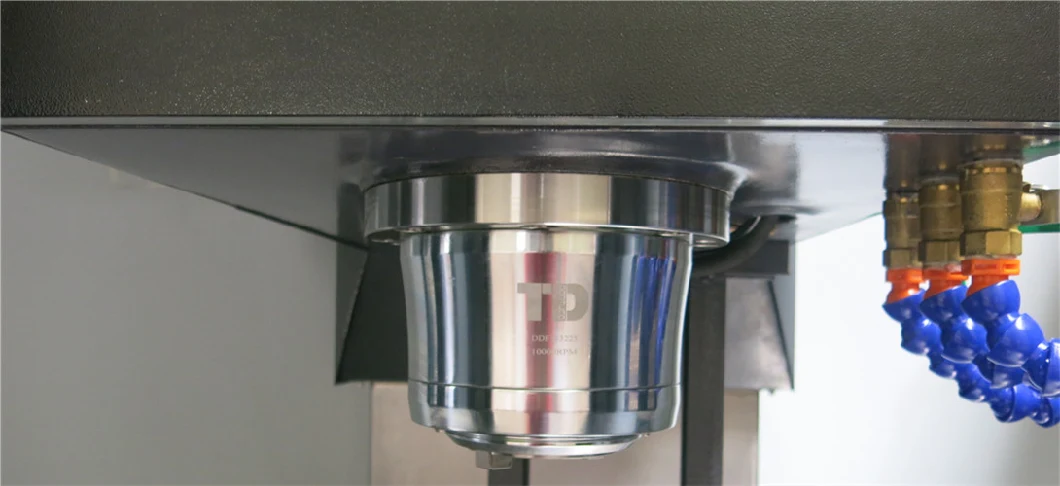

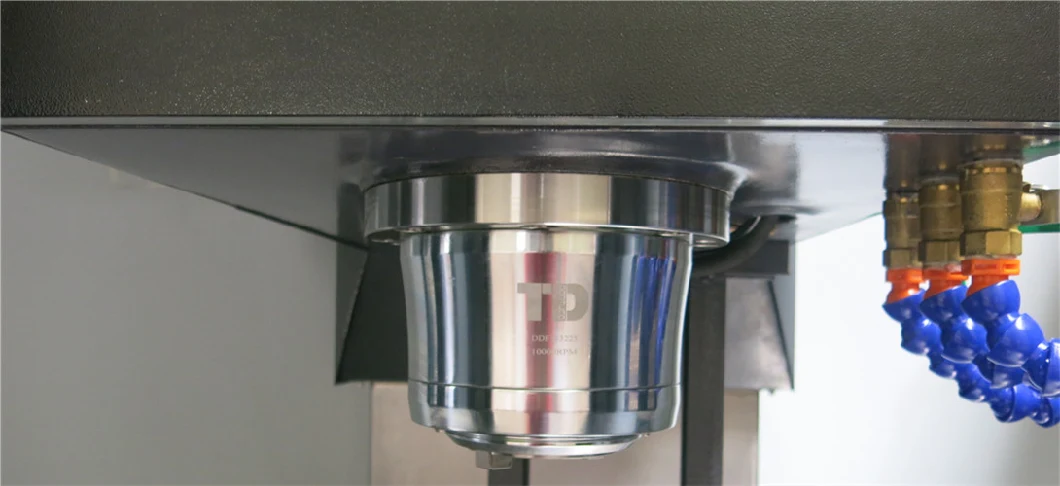

Spindle

Taiwan Wlt / Td, 12000 Rpm ,Direct Connection

Spindle Taper

Bt40

Spindle Motor

11kw

Cutting Speed

0-10000mm/Min

Transport Package

Wooden Packing

Specification

3820*2750*2600mm

Trademark

Chansin

Origin

China

HS Code

8457101000

Production Capacity

1000sets/Year

Product Description

Donggaun company Metal Moulds Cutting Processing universal Vmc CNC milling machine (TC-1270)

Features:

* cast iron high strength body

* Taiwan Syntec,Japan MITSUBISHI,Fanuc, Germany Siemens nc system

* Taiwan spindle BT40 belt drive

* Hiwin/PMI ball screw

* NSK bearing

* HIwin linear guide rails

* The cutting of the cooling system

* Full enclosed guard

* Automatic lubricating system

* Mechanical abnormal alarm trichromatic lamp

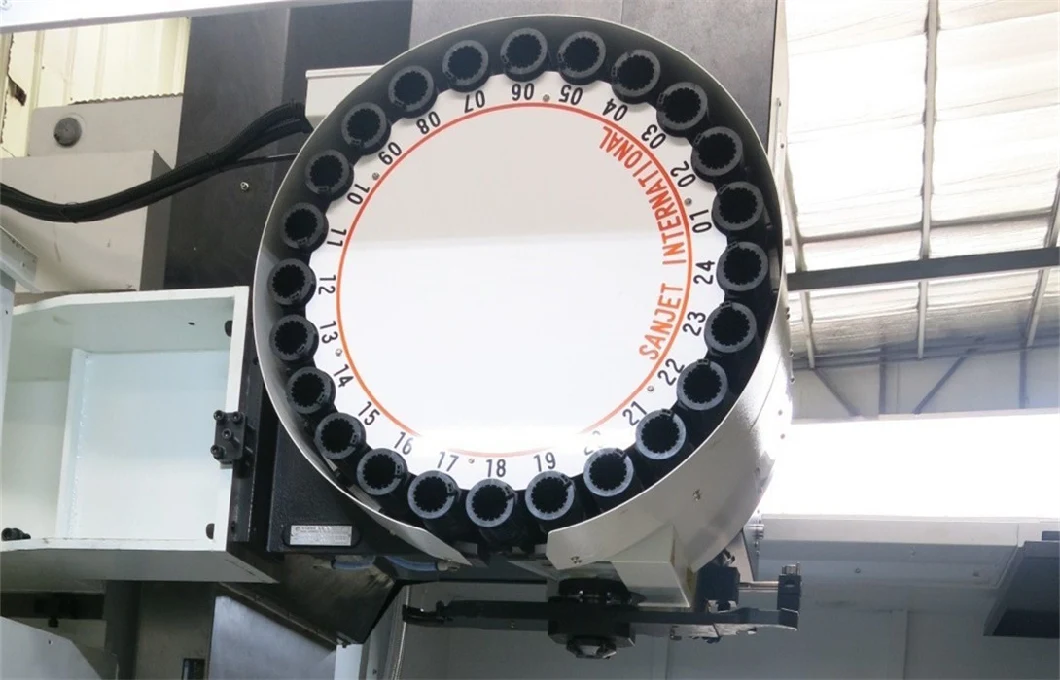

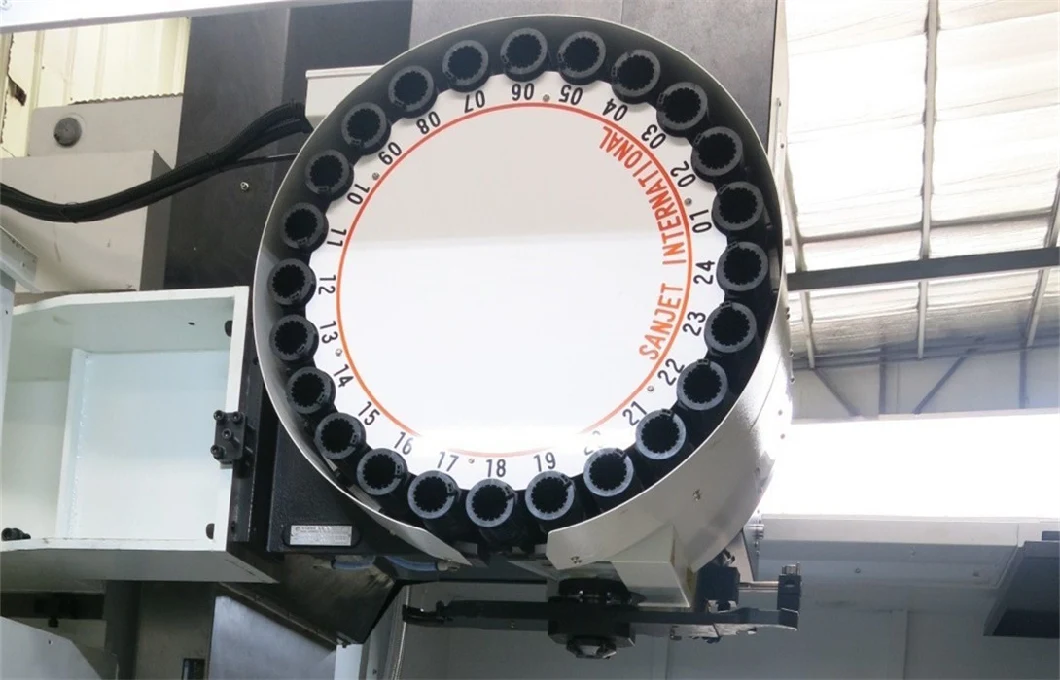

* BT40 arm type tool magazine (tool changing 1.8 sec)

Specifications of TC-1270:

Payment Term:

Payment:40% deposit,the balance will be paid before shipping.

Delivery:

20-30 days after received the deposit payment.

Remarks:

1.Warranty:One year free warranty and life time maintenance.

2. Loading port: Shenzhen/Guangzhou

3.Engineers are available to serve overseas, you are responsible for the air tickets and accommodations expenses. The price above is not including this expenses.

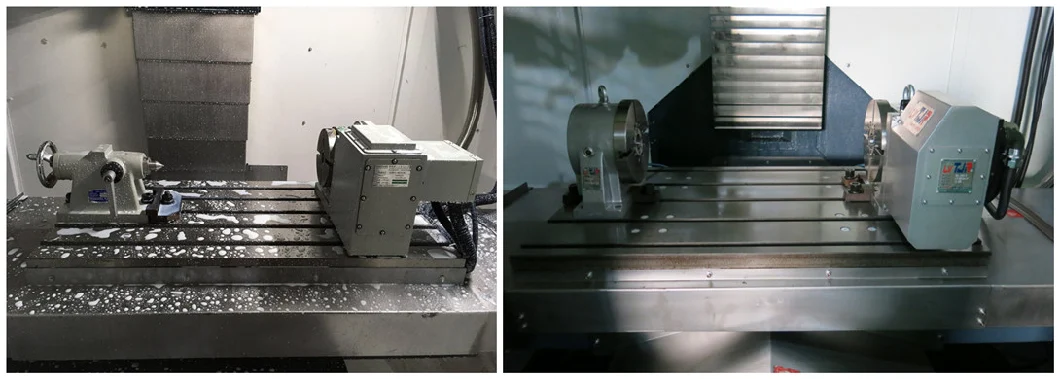

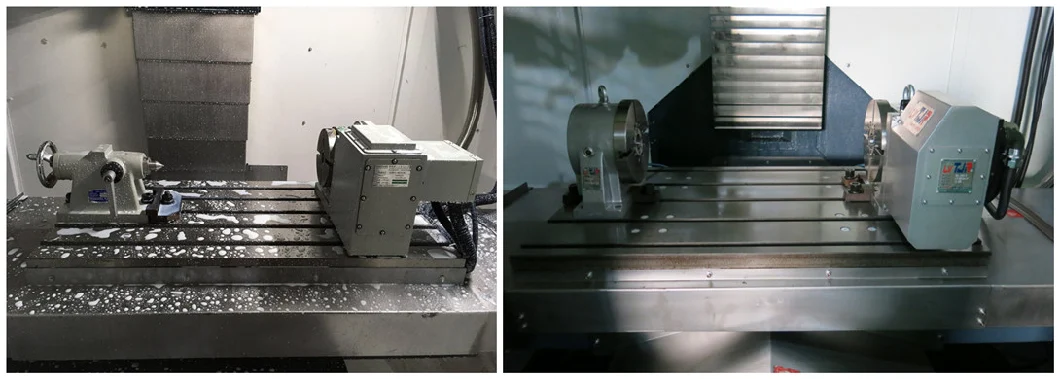

4th/5th rotary table optional:

Our certificates:

Part of Our Customers:

Features:

* cast iron high strength body

* Taiwan Syntec,Japan MITSUBISHI,Fanuc, Germany Siemens nc system

* Taiwan spindle BT40 belt drive

* Hiwin/PMI ball screw

* NSK bearing

* HIwin linear guide rails

* The cutting of the cooling system

* Full enclosed guard

* Automatic lubricating system

* Mechanical abnormal alarm trichromatic lamp

* BT40 arm type tool magazine (tool changing 1.8 sec)

Specifications of TC-1270:

| Machine Body | Casting three linear guide ways high-strength body |

| Spindle | original import Taiwan WLT / TD, 12000 rpm ,direct connection |

| System | Original Japan imported control system the latest version Mitsubishi M80A |

| Spindle motor | Imported Japan Mitsubishi servo motor 11KW |

| Three-axis motor | Imported Japan Mitsubishi servo motor |

| Automatic lubrication system | pressurized volumetric automatic oiler, automatic balance distribution of lubricants (joint venture Baoteng brand oiler) |

| Head balance system | The body comes with a counterweight balancing system |

| High pressure chip system | high pressure motor, high pressure flushing (joint venture Sinaer brand water pump) |

| Screw | original Taiwan imported Hiwin screw |

| Spindle cooling | plus independent oil cooling system (joint venture Ruike brand oil cooler) |

| Tool Magazine | Taiwan Sanjie arm type with 24 BT40 tools capacity |

| Controller | standard Mitsubishi M80A color display |

| X, Y, Z bearings | standard German FAG or Japan NSK |

| Triaxial roller screw | standard Taiwan Taiwan Hiwin / PMI |

| Spindle Knife cylinder | Standard Taiwan North Kui / Hao Cheng |

| Couplings | Standard Germany BK3 SW*J |

| Wind system combined with solenoid valve (triple) | standard joint venture Ogreut |

| The main electrical accessories | standard Germany Schneider, Merlin Gerin |

| Other air pressure components | standard joint venture Ogreut |

| Circuit breakers, relays | standard Germany Schneider, Merlin Gerin |

| Electric box air fan | standard joint venture FuRuize |

| Transformer | standard joint venture AoHengda |

| Work LED lamp | standard Taiwan Ou Si |

| Hand control electronic hand wheel | standard Taiwan NEMICON |

| Three-axis telescopic shield | standard joint venture Zhenfei |

| Full cover | standard joint venture Jiancheng |

| X/Y/Z-Axis Travel | 1200/700/600mm |

| Distance from Spindle Nose to Table | 150-750mm |

| Distance from Spindle Center to Column Guide Rail | 785mm |

| Working Table Size | 1360*700mm |

| Table Max Load | 1300kg |

| T Slot | 5pcs,size:18T |

| Spindle Speed | 12000rpm |

| Spindle Motor Power | 11kw |

| X/Y/Z-Axis Motor Power | 3.0/3.0/3.0kw |

| Rapid Traverse(X/Y/Z) | 24000mm/24000mm/24000mm/min |

| Cutting Speed | 0-10000mm/min |

| Spindle Taper Diameter | BT40/150mm |

| Positioning Accuracy | ±0.005mm/500mm |

| Repeat Positioning Accuracy | ±0.003mm/500mm |

| Total Electricity Demand | 25kw |

| Machine Size | 3820*2750*2600mm |

| Machine Weight | 10.5ton |

| Accessories |

|

Payment Term:

Payment:40% deposit,the balance will be paid before shipping.

Delivery:

20-30 days after received the deposit payment.

Remarks:

1.Warranty:One year free warranty and life time maintenance.

2. Loading port: Shenzhen/Guangzhou

3.Engineers are available to serve overseas, you are responsible for the air tickets and accommodations expenses. The price above is not including this expenses.

4th/5th rotary table optional:

Our certificates:

Part of Our Customers: